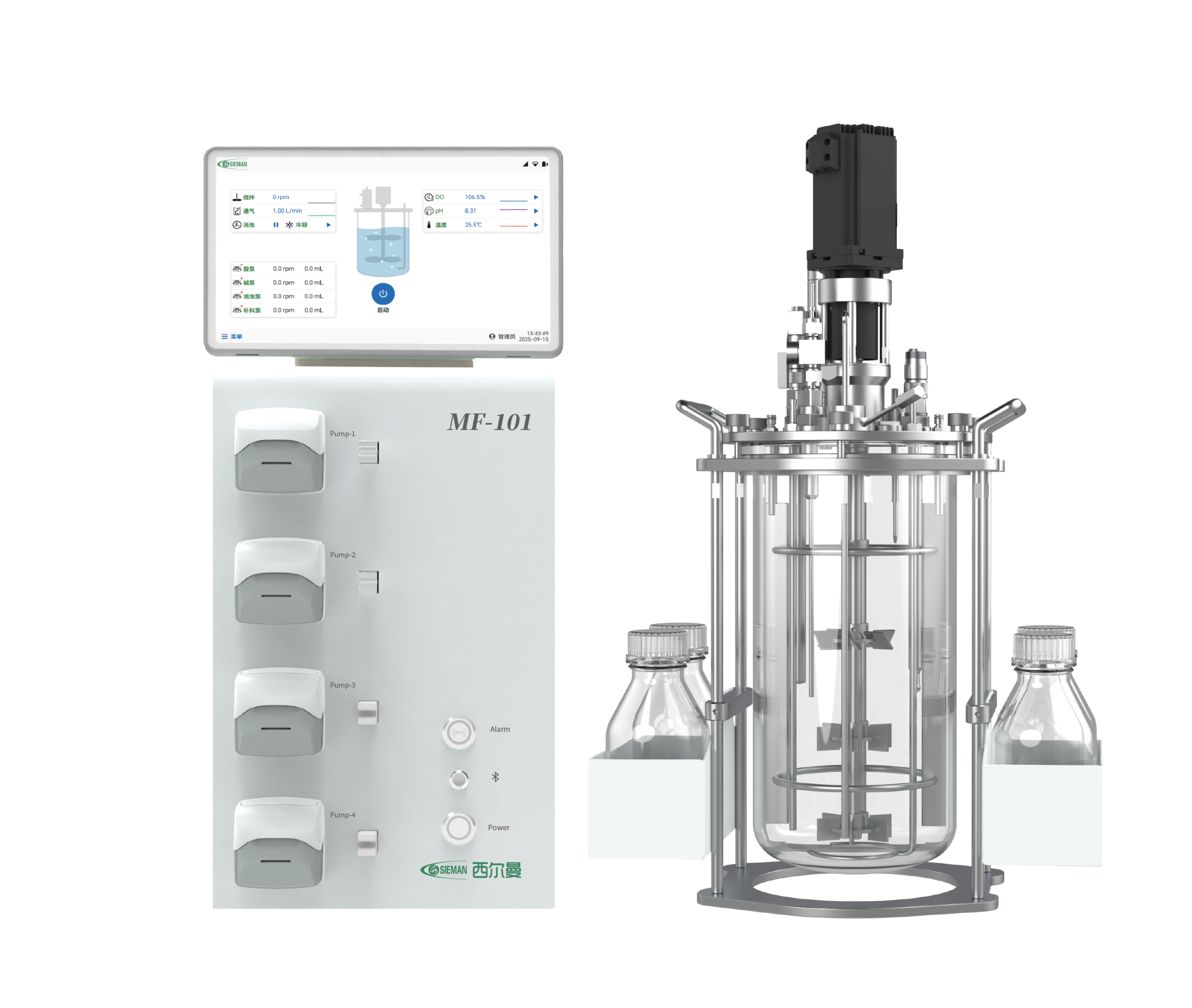

MF-101 Bioreactor

MF-101 Bioreactor: Utilizes highly integrated MCU control with precision algorithms for superior cultivation management

SEND YOUR REQUESTS

MF-101 Bioreactor

Self-Developed Microbial Cultivation System

-

Advanced Control Technology

Utilizes highly integrated MCU control with precision algorithms for superior cultivation management -

Proprietary Intelligent PID Control

Fully self-developed system incorporating Sieman’s proprietary pH/DO sensors for unmatched process control -

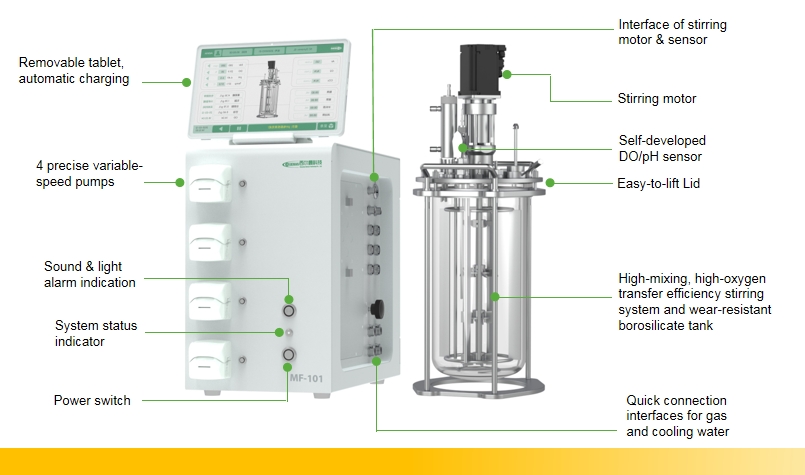

Smart Touch Console

Features a detachable tablet with:

✓ Microsecond response time

✓ Integrated sensor signal processing

✓ Intuitive HMI interface

✓ Wireless connectivity (Wi-Fi/Bluetooth) -

Cloud-Connected Platform

Seamless integration with Sieman Software Suite for:

• Experimental design

• Bioreactor scale-up calculations

• Fluid dynamics simulation

MF-101 Bioreactor Characteristics

- It adopts a high-performance ARM chip design to achieve more precise culture control

- Wireless portable tablet, unlimited space for free control

- Self-developed digital sensors are adopted to deeply and intelligently collaborate with the reactor

- Flexible PID intelligent control algorithm, with configurable relevant parameters

- The configuration parameters can save to the template for convenient invocation and start running with one click

- Simple and humanized human-computer interaction interface design

- Data curve can be selected with multiple parameters, and multiple batches can be compared and viewed. The data and curve can be exported

- 4 Level user management authority, supports audit trail function, complies with FDA 21 CFR Part 11

- It can be connected to a mobile phone APP to achieve remote control

- It can be interconnected to the Sieman software platform, supporting DoE, scale-up calculation, etc

- Independent and controllable, and the after-sales service response is fast

- Equipped with all the necessary components, it is ready to use right out of the box

MF-101 Bioreactor Application

- High-density fermentation of yeast

- High-density fermentation of E.coli

- High-density fermentation of Bacillus subtilis

- Microbial culture in synthetic biology

- Fungal fermentation culture

MF-101 Bioreactor Intelligent System

The MF-101 bioreactor is a complete and intelligent bioreactor system specifically optimized for microbial fermentation. This ready-to-use system comes fully equipped with all essential components and features:

-

Advanced Control Architecture

High-integration, cost-effective microcontroller system enabling sophisticated control algorithms -

Seamless Workflow Integration

Detachable touch tablet bridges experimental operations with data processing -

High-Density Fermentation Specialist

Ideal for yeast, E. coli, B. subtilis, and fungal cultures -

Regulatory-Compliant Design

GMP-aligned environment with closed-loop data control

FDA 21 CFR Part 11 compliance including audit trail functionality -

Flexible Configuration

Vessel volume options (3L/5L)

Compatible with Sieman software platform for DoE and scale-up calculations -

Proprietary Sensing Technology

Self-developed DO sensors (optical/polarographic options available)

Precise, transparent measurements with independent IP

Technical Advantages

✓ 100% independent core technologies

✓ Significantly improved fermentation success rates

✓ Enhanced data processing efficiency

✓ Rapid customization services

A next-generation fermentation solution bridging R&D to production

MF-101 Bioreactor Technical Specifications Table

| Parameter | Specifications |

|---|---|

| System | Sieman MF-101 Control System |

| Tank | – Single-wall borosilicate glass – 316L stainless steel cover plate – Integrated agitator – Gas distributor – Support frame |

| Volume | 5L / 3L (selectable) |

| Ventilation | Annular bottom ventilation (30×φ1mm openings) |

| Exhaust | Condenser exhaust system |

| Sampling | Manual offline sampling port |

| pH Control | – Cascade control with acid/alkali pumps – Range: 0-14 – Accuracy: ±0.01 |

| Temperature | – PT-100 sensor – Range: 5-80°C – Accuracy: ±0.1°C – Programmable sequence control |

| DO Control | – Integrated with ventilation/stirring – Range: 0-150% – Accuracy: ±0.1% – Programmable sequence control |

| Defoaming | – Automatic liquid level detection – Pump-controlled defoamer addition |

| Tank Interface | – Modular standard interfaces – Flame-resistant inoculation port – Configurable port switching |

| Screen | Portable touch tablet controller |

| Gas Flowmeter | High-precision mass flowmeter (0-10L/min range) |

| Pump System | 4 × precision variable-speed pumps |

| Process Monitoring | – Complete parameter curve recording – Real-time data visualization |

| Data Compliance | – FDA 21 CFR Part 11 compliant – Audit trail functionality – Full data export capability |

| Control Algorithm | Adaptive PID intelligent control |

| Software Integration | – Sieman software platform connectivity – Supports DoE (Design of Experiments) – Scale-up research capabilities |

Service Commitment

We are committed to providing customers with efficient and professional after-sales service to ensure the stable operation of the equipment. The commitments are as follows:

Rapid response: Respond within 2 hours after receiving a service request and provide a solution within 48 hours (except for remote areas).

Professional technical support: On-site technical support or remote assistance is provided by Silman’s experienced after-sales engineer team.

Original factory parts guarantee: All repair and replacement parts are produced by the original factory to ensure independent compatibility and performance stability.

Lifetime service: Provide technical support throughout the entire life cycle of the equipment, including software upgrades, technical support, maintenance and care guidance, etc.