8. FC Optical DO Sensor —— Exact

FC Optical DO Sensor allows accurate and timely monitoring of dissolved oxygen values, supports wireless Bluetooth connection to diagnose sensor status

SEND YOUR REQUESTS

FC Optical DO Sensor Introduction

We have launched the high temperature resistant and accurate value reading optical dissolved oxygen sensor — FC Optical DO Sensor. This innovative product is designed for processes such as high temperature steam sterilization and CIP process, ensuring stable and reliable DO value reading under harsh conditions.

The FC optical dissolved oxygen sensor has a self-diagnostic function to inspect and report the status of the sensor in time, it improves the reliability and stability of the production process. And it uses an electrolyte-free design to avoid the impact of electrolyte changes on the measurement accuracy. In addition, our sensors require no polarization time to respond quickly and perform dissolved oxygen measurements, increasing production efficiency.

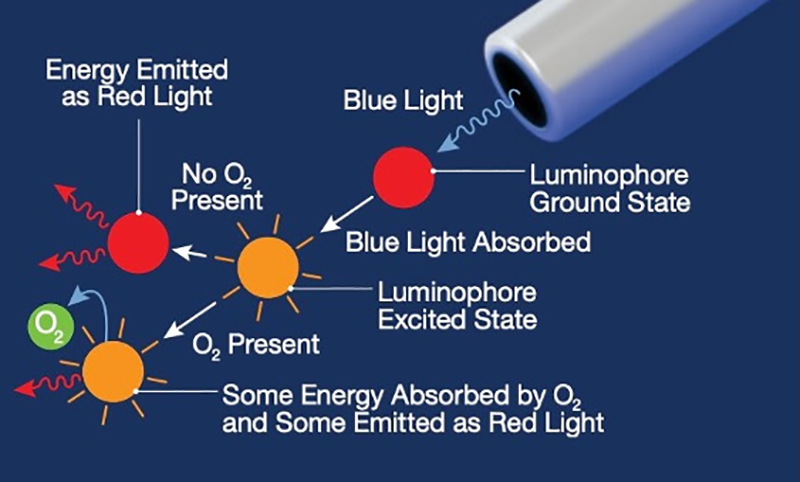

FC Optical DO Sensor Principle

Sieman FC optical DO sensor is working on the principle of fluorescence quenching as shown in the following picture:

FC Optical DO Sensor Features

1.High temperature design: specially designed for multiple high temperature steam sterilization and cleaning (CIP) processes, to ensure stable and reliable reading under harsh conditions.

2.Self-diagnosis: with self-diagnosis function, automated search and report the sensor status in time, improve the reliability and stability of the production process.

3.No electrolyte: the electrolyte-free design to avoid the impact of electrolyte changes on the measurement accuracy, to ensure continuous and stable measurement performance.

4.No polarization time: no need to wait for the polarization time, quickly respond and measure dissolved oxygen, improve production efficiency.

5.Easy to replace optical oxygen cap: optical oxygen cap is easy to replace, convenient maintenance.

6.Start intelligent: provide digital and analog signal output, suitable for different monitoring and control systems to meet diverse needs.

7.ECS mode optional: With ECS mode, similar to Clark method simulation, providing more testing and control options.

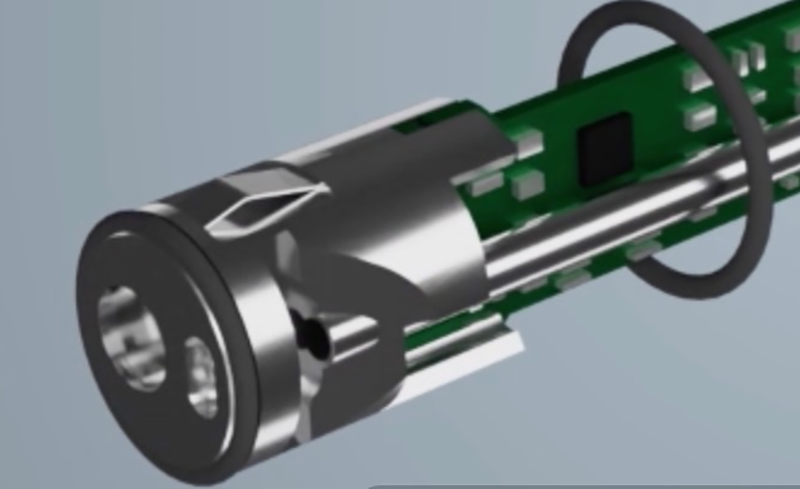

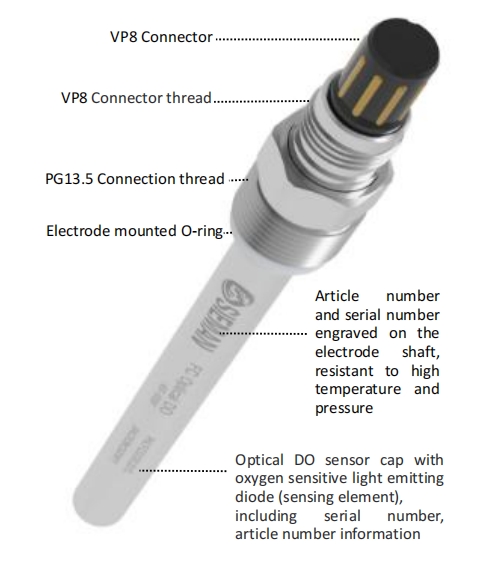

FC Optical DO Sensor Structure

The Sieman optical dissolved oxygen sensor consists of an induction VP connector with integrated internal circuit, PG13.5 thread, O-ring, sensor probe rod, and optical dissolved oxygen sensor cartridge connected to the sensor shaft.

The sensor cartridge is composed of oxygen sensitive luminescent group material, light transmittable glass, and isolation layer material. The isolation layer has no dissolved substance during contact with the liquid, and the material meets the safety production requirements. The stainless steel surface of the sensor shaft is completely polished, the material is strong and pressure resistant, and it also meets the relevant requirements of safety production. The overall design also meets the health standards. Motor shaft stainless steel heat goods number also withstands high temperature and pressure without any damages.

FC Optical DO Sensor Technical Parameter

| Sensor Type | Optical Dissolved Oxygen |

| Length | 120/160/225/325/425 mm |

| Circuit connector | VP8 |

| Principle | Fluorescence quenching |

| Measuring range | 0~300 %-Sat

4~25ppm(DO) 0~62.85%-vol |

| Accuracy

(25℃) |

1±0.05 %-vol;

21±0.2 %-vol; 50±0.5 %-vol. |

| Drift at RT | < 1 % per week |

| Temperature sensor | NTC 22 KOhm |

| Configurable unit | %-sat;

%-vol; mbar; µg/L (ppb); mg/L (ppm); |

| Diameter | 12mm |

| Connect type | PG13.5 |

| Liquid contact component material | Stainless steel 316L

PTFE EPDM |

| Stainless steel surface polishing | Ra < 0.4 µm (N5) |

| Analog interface | ECS(nA), 4-20mA |

| Digital interface | RS485 |

| Baud rate | 4800, 9600, 19200, 38400, 57600, 115200 |

| Working voltage | 12~30 VDC |

| Response time | t98% < 60 s ( 25 °C) |

| Certificate | Including factory certification, material testing, etc |

| SIP | Support, tolerate 130℃ |

| CIP | Support |

| Operating temperature range | -10 ~ 140℃;

not provide DO readings above 60°C |

| Pressure range | -1 ~ 12 bar |

BW-01 wireless adapter

Sieman BW-01 Wireless Adapter provides wireless communication between Sieman optical dissolved oxygen sensors and Sieman pH smart sensors to mobile devices or computers via Bluetooth low power consumption 5.0 or 2.4GHz Wi-Fi (802.11 b/g/n).

After installing the “Sieman Sensor APP” on your mobile device or computer and connecting it, you can view the sensor’s information, real-time measurement data and current status, it can also calibrate the sensor and configure the sensor parameters. The adapter supports both analog and digital signals of the sensor while transmitting smoothly, it is designed for immediate installation and immediate use, compatible with Sieman optical dissolved oxygen sensors with VP connectors and pH intelligent sensors.

Here is the video about how to calibrates and reads the sensor information by using a mobile device connected to a wireless Bluetooth adapter.

FC Optical DO Sensor Order Information

| Product Name | Art. No. |

| AS-1000 Optical DO Sensor 120 | FCDO ECS 12 120 |

| AS-1000 Optical DO Sensor 160 | FCDO ECS 12 160 |

| AS-1000 Optical DO Sensor 225 | FCDO ECS 12 225 |

| AS-1000 Optical DO Sensor 325 | FCDO ECS 12 325 |

| AS-1000 Optical DO Sensor 425 | FCDO ECS 12 425 |

| AS-3000 Optical DO Sensor 120 | FCDO 420 12 120 |

| AS-3000 Optical DO Sensor 160 | FCDO 420 12 160 |

| AS-3000 Optical DO Sensor 225 | FCDO 420 12 225 |

| AS-3000 Optical DO Sensor 325 | FCDO 420 12 325 |

| AS-3000 Optical DO Sensor 425 | FCDO 420 12 425 |

| Sensor membrane cap sealed O-ring | MPO2002 |

| Sensor installation sealed O-ring | MPO2003 |

| Biofluorescence DO Sensor Cap | MPO2004 |

| VP Cable 1M | PJ-VP-0001 |

| VP Cable 3M | PJ-VP-0003 |

| VP Cable 5M | PJ-VP-0005 |

| VP Cable 10M | PJ-VP-0010 |

| VP Cable 15M | PJ-VP-0015 |

| VP Cable 20M | PJ-VP-0020 |

| VP Cable 30M | PJ-VP-0030 |