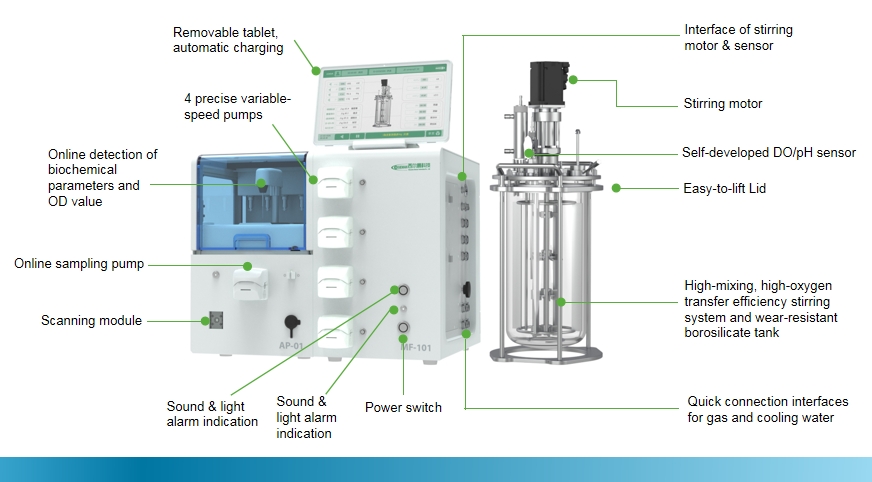

AMF-101 Integrated Online Bioreactor

The AMF-101 Integrated Online Bioreactor can achieve real-time monitoring and dynamic regulation of parameters such as biochemical parameters and OD values

SEND YOUR REQUESTS

AMF-101 Integrated Online Bioreactor

The AMF-101 Integrated Online Bioreactor features a removable touchscreen panel and a highly integrated control system, incorporating sterile microfluidic channels. It enables real-time monitoring and dynamic regulation of biochemical parameters, OD values, and other critical metrics, supporting complex metabolic control processes.

The Era of Affordable, Integrated Online Bioreactors Has Arrived

Smart Metabolic Control | Precision Fermentation

Core Proprietary Technologies | Real-time Biochemical Analysis | Real-time OD Monitoring | Closed-loop Process Control

AMF-101 Integrated Online Bioreactor Key Features

-

Integrated sterile auto-sampling flow path enables online biochemical detection and intelligent closed-loop control

-

Novel optical technology for online OD monitoring, dynamic feeding strategy adjustment, and precise induction

-

High-performance ARM chip design for refined cultivation control

-

Wireless movable tablet for unrestricted remote operation

-

Proprietary digital sensors with deep intelligent reactor coordination

-

Flexible PID control algorithm with configurable parameters

-

Save parameter templates for one-click operation in subsequent runs

-

Multi-parameter batch comparison with exportable data/curves

-

Four-tier user management with audit trail (FDA 21 CFR Part 11 compliant)

-

Mobile APP connectivity for remote control

-

Compatible with Silverman Software Platform (experimental design, scale-up calculations)

-

Domestic supply chain ensures rapid after-sales support

-

Fully equipped for plug-and-play operation

AMF-101 Integrated Online Bioreactor Application Cases

-

Yeast High-Density Fermentation

-

Real-time glycerol monitoring (for Pichia pastoris induction)

-

Precise methanol feeding to avoid toxicity accumulation

-

-

E. coli High-Density Fermentation

-

Real-time OD/glucose monitoring

-

Automatic specific growth rate calculation for optimized feeding/induction

-

-

Synthetic Biology

-

Multi-parameter co-analysis for high-yield strain screening

-

Reliable small-scale process development

-

-

PHA (Biodegradable Plastic) Production

-

Glucose feedback optimizes carbon flux allocation

-

PHA yield increased from 30% to 45% with PDI <1.3

-

-

Beer Continuous Fermentation

-

Ethanol/glycerol monitoring reduces fermentation variability (±5% → ±1%)

-

40% improvement in flavor stability via maltose closed-loop control

-

AMF-101 vs. Traditional Bioreactors: A Paradigm Shift in Bioprocessing

The AMF-101 represents a breakthrough in real-time analytical control, data-driven optimization, process stability, and end-to-end efficiency—particularly tailored for high-value biopharmaceutical production (e.g., antibiotics, monoclonal antibodies, vaccines) and complex metabolic engineering research.

Key Advantages

▸ Configurable Scalability

-

Available in 3L/5L working volumes

-

Modular design allows customized add-on/reduction of components

-

Supports up to 8 real-time monitoring parameters with closed-loop feedback for precision cultivation

▸ Regulatory-Compliant Intelligence

-

Fully aligns with current GMP requirements

-

Implements closed-loop data control for dynamic parameter adjustment and feeding strategy optimization

-

Ensures data integrity (FDA 21 CFR Part 11 compliant) with full audit trail capability

▸ Technological Leap

-

Transforms bioreactors from mere “production vessels” into intelligent metabolic control systems

-

Achieves generational advancements in biomanufacturing accuracy, efficiency, and autonomy through deep integration of proprietary technologies

AMF-101 Integrated Online Bioreactor Specifications

| Item No. | Item | Description |

|---|---|---|

| 1 | Bioreactor Vessel | 5L single-wall borosilicate glass vessel, 316L stainless steel headplate, 2×Rushton impellers, 1×down-pumping pitched-blade impeller, 1×antifoam impeller, gas distributor and frame |

| 2 | Control Software | Sieman Intelligent Control Software |

| 3 | Controller & Tablet | Sieman MCU control system with removable color touchscreen |

| 4 | Data Management System | Sieman LIS Data Management System |

| 5 | Agitation | Range: 0-2000 rpm, Accuracy: ±1 rpm |

| 6 | Aeration | Annular bottom sparger with 30×Φ1mm holes |

| 7 | Exhaust | High-efficiency water condenser |

| 8 | Sampling System | Includes quantitative module and sterilizable tubing, sterile auto-sampling probe, configurable parameters (min 2mL), optional sample return feature |

| 9 | pH | Cascade control with acid/base pumps, sequential control, Range: 0-14, Accuracy: ±0.01, sequential control supported |

| 10 | Temperature | Pt100, sequential control supported, Range: 5-80°C, Accuracy: ±0.1°C |

| 11 | Heating Blanket | N/A |

| 12 | DO (Dissolved Oxygen) | Optional Sieman optical/polarographic DO probe, cascade with air/agitation, Range: 0-150%, Accuracy: ±0.1%, sequential control supported |

| 13 | Antifoam | Level sensor detection with automated pump dosing |

| 14 | Vessel Ports | Modular standard ports with flame-sterilizable inoculation port, supports PG13.5 threaded sensors |

| 15 | Bottom Drain | Drainage piping |

| 16 | Gas Flowmeter | High-precision mass flow meter (0-10L/min) |

| 17 | Pumps | 4× programmable precision pumps (0-500 rpm), 1× online sampling bidirectional pump |

| 18 | Feed Bottles & Caps | 6×500mL high-temp borosilicate glass bottles with high-seal caps and Robert clamps |

| 19 | Silicone Tubing | 16# sterilizable silicone tubing (15m/roll) |

| 20 | Air Filters | Sartorius 0.22μm air filters |

| 21 | Process Curves | Complete parameter logging with detailed data inspection |

| 22 | Data Compliance | Independent closed-loop data system, FDA 21 CFR Part 11 compliant (audit trail + export) |

| 23 | PID Control | Intelligent PID algorithm |

| 24 | Software Integration | Compatible with Sieman platform (DoE, scale-up studies, fluid analysis) |

| 25 | Biochemical Parameters | Real-time monitoring of glucose, lactate, glutamate, glutamine, glycerol etc. with automated feed control |

| 26 | OD Measurement | Real-time OD monitoring, specific growth rate calculation for precision feeding/induction |

| 27 | Gaskets & O-rings | – |

| 28 | 3Q Validation Docs | Installation/Operation/Performance Qualification documentation |